These alloys are tarnish resistant and show low rates of corrosion in atmospheric conditions low oxidation rates at high temperatures and low reactivity with sulfurous compounds and other exhaust products of combustion.

Nickel aluminum bronze corrosion resistance.

This film is self repairing in media containing even low levels of oxygen.

Corrosion rate 0 05 0 075 mm year impingement resistance up to 4 3 m sec nb.

This is due to its light weight but also to its resistance to.

Nickel aluminum bronze nab is copper aluminum alloy with addition of nickel and iron elements.

Nickel aluminum bronze alloys are known their superior corrosion resistance in seawater and many other chemical environments.

Centrifugally cast nickel aluminum bronze high pressure flange for a sub sea weapons ejection system.

Alloy c95800 was selected for this application for its combination of high yield strength 35 ksi 241 mpa minimum as cast excellent seawater corrosion resistance and galvanic compatibility with mating materials.

04 nickel aluminum bronze alloys are known for their superior corrosion resistance in seawater and many other chemical environments.

Their strength is similar to that of medium carbon steel and they possess excellent corrosion resistance though aluminum bronzes possess many other valuable characteristics.

The corrosion resistant property relies on the formation of a copper aluminum oxide film.

Aluminum bronze aluminum bronzes are a family of copper based alloys containing aluminum as the principle alloying element.

This oxide film provides the following benefits.

Other elements in the alloy such as nickel and molybdenum add to its rust resistance.

State of the art review of seawater corrosion resistance and antifouling of copper nickel cupronickel alloys covering 90 10 and 70 30 alloys.

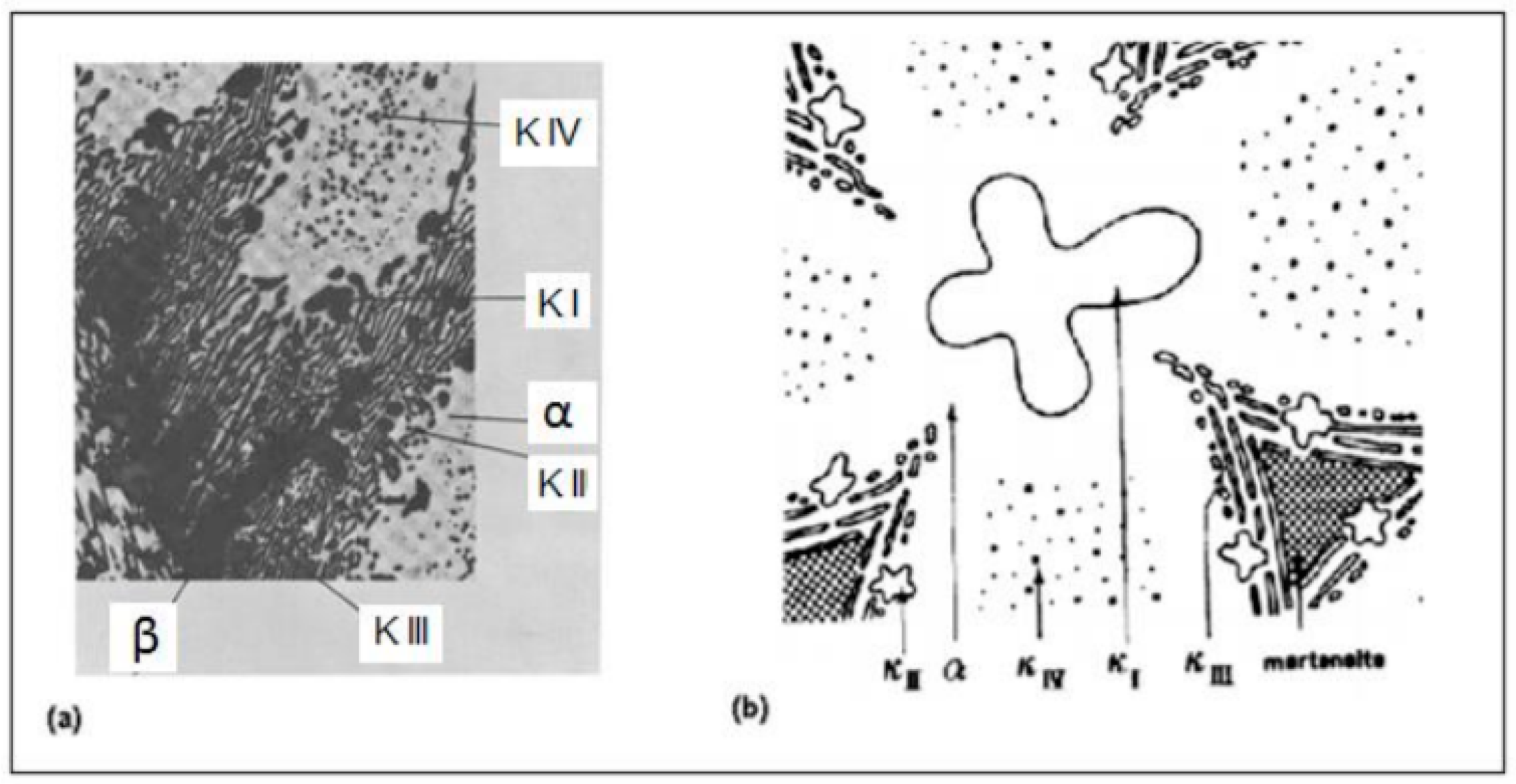

While displaying a good combination of corrosion resistance and strength nab is still prone to different forms of corrosion such as stagnant sea water corrosion selective phase corrosion and cavitation erosion.

This film is self repairing in media containing even low levels of oxygen.

Nickel aluminum bronze nab is a metallic alloy that is widely used for ship valves and propellers among other marine applications.

This paper examines surface films localised corrosion sand erosion galvanic issues sulfides and ferrous sulfate treatments as well as biofouling boat hulls and offshore sheathing.

Many aircraft are made from aluminum as are car and bike parts.

It is widely used as pipes valves and pump casings in marine environments due to the excellent.

This oxide layer resists corrosion while at the same time prevents oxygen from reaching the underlying steel.