The mandrel is encased within the blind rivet itself.

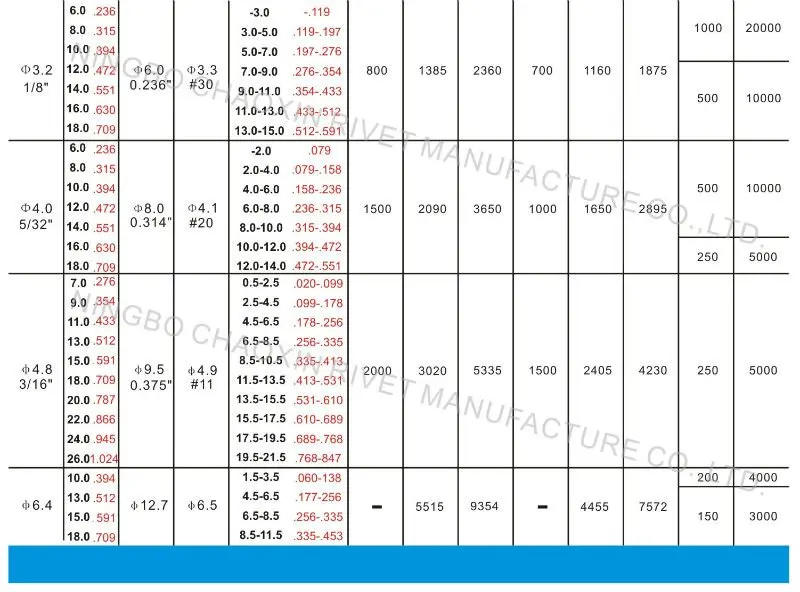

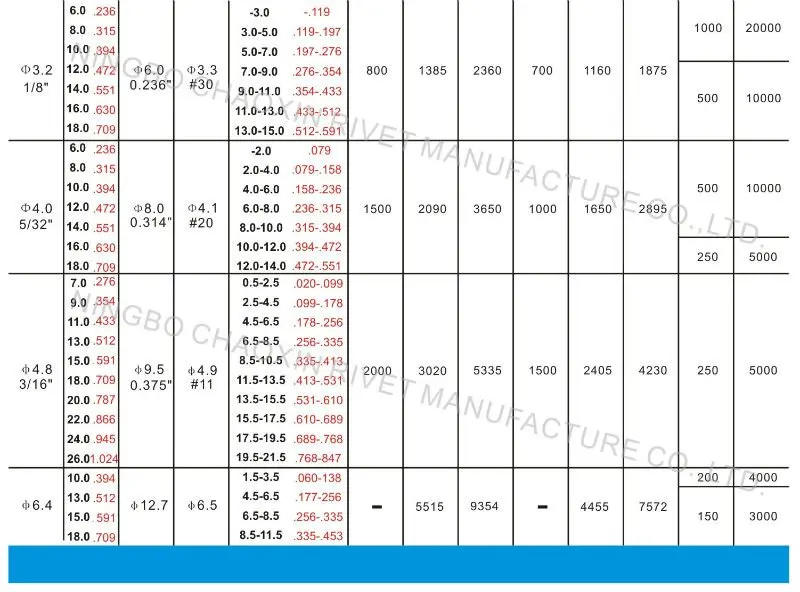

Standard blind rivet sizes.

American standard ifi 114 rivets american standard inch series blind rivets are manufactured to ifi 114 specifications.

Choosing the right size of blind rivet.

Otherwise maintain the normal edge distances both visible and invisible.

1 or 2 and bend radius tangent point.

The most common way to specify a rivet size is by trade size.

Link to the rapid range of standard blind rivets.

Use the table below to determine the.

Also known as button head rivets this style has a rounded head with a lower profile than standard round head rivets.

Measure the grip range.

Also aluminum rivets with aluminum mandrels are the least strong.

They are available in dome large flange and countersunk head styles.

This specific style of steel dome headed blind rivets is coated with zinc cr 3 to provide resistance to corrosion.

Closed end pop rivets differ from a standard pop rivet in that they feature a flat closed end which creates a watertight seal.

Indicates sizes normally used for oversize replacement only.

They are universal because they can be used in place of any rivet head style round flat brazier etc.

When sizing blind rivets the larger the size the stronger the fastened joint in both shear and tensile.

The grip range corresponds to the total thickness of the materials being joined together.

Provide a minimum of 03 between the edge of non flush rivet heads nos.

Diameter and spacing of the blind rivets.

Material thickness each blind rivet is engineered for a specific range of material thickness for which it will be effective.

This range of material or work thickness is the blind rivet s grip range.

3 32 1 8 5 32 3 16 1 4.

Typical examples of unacceptable rivets.

Hole size proper hole size is important to ensure the in tegrity of the fastened joint.

The second number refers to the maximum grip length in 16ths of an inch.

Steel zinc cr 3 dome head blind rivet steel standard blind rivets have greater tensile strength and shear values that other materials.

Also known as a waterproof rivet they are distinguished by their flat top.

The first number refers to the diameter of the rivet in 32nds of an inch.

Trade sizes part numbers.

Have a head that lays flat on the part or material surface.

Steel rivets with steel mandrels are stronger still.

All aluminum aluminum rivet w steel mandrel all steel stainless rivet w steel mandrel and all stainless.

And stainless steel rivets with either steel or stainless steel mandrels are the strongest.